-

First aid is emergency care provided for injury or sudden illness before emergency medical treatment arrives. Most companies are required to have a first-aid provider trained in first aid and CPR to intervene while waiting for Emergency Medical Service (EMS). Enclosed are documents to help you better investigate accidents, respond to medical emergencies and to comply with OSHA.

First aid is emergency care provided for injury or sudden illness before emergency medical treatment arrives. Most companies are required to have a first-aid provider trained in first aid and CPR to intervene while waiting for Emergency Medical Service (EMS). Enclosed are documents to help you better investigate accidents, respond to medical emergencies and to comply with OSHA. -

PPE is designed to protect workers from workplace injuries or illnesses resulting from contact with physical, mechanical, chemical, radiological, electrical or other workplace hazards. PPE is important because creates a barrier against workplace hazards thus reducing risk of injury. Provided resources can help you conduct the PPE Hazard Assessment, employee training and much more.

PPE is designed to protect workers from workplace injuries or illnesses resulting from contact with physical, mechanical, chemical, radiological, electrical or other workplace hazards. PPE is important because creates a barrier against workplace hazards thus reducing risk of injury. Provided resources can help you conduct the PPE Hazard Assessment, employee training and much more. -

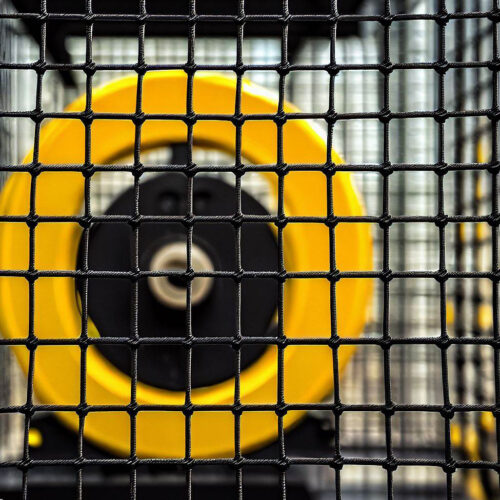

Forklifts are involved in about 85 fatalities and 7,000 serious injuries per year. Accidents frequently involve tip-overs, loads falling and crushing people, and hitting pedestrians. OSHA imposes many safety requirements including training and inspections. The documents and resources provided here can help you reduce the risk of accidents and improve your knowledge and handling your forklift program.

Forklifts are involved in about 85 fatalities and 7,000 serious injuries per year. Accidents frequently involve tip-overs, loads falling and crushing people, and hitting pedestrians. OSHA imposes many safety requirements including training and inspections. The documents and resources provided here can help you reduce the risk of accidents and improve your knowledge and handling your forklift program. -

Protect the individual wearer against the inhalation of hazardous substances and/or an oxygen-deficient atmosphere. Hazards include serious injury and death. Major requirements are a written program, annual training, medical evaluation and fit testing. We have just about everything you need, right here, to get the job done.

Protect the individual wearer against the inhalation of hazardous substances and/or an oxygen-deficient atmosphere. Hazards include serious injury and death. Major requirements are a written program, annual training, medical evaluation and fit testing. We have just about everything you need, right here, to get the job done. -

Scissor lifts are a type of Aerial Lift used to safely move workers vertically. OSHA regulates scissor lifts under the “Scaffolding Standard”. Hazards include falling from lifts, tipping over, and being crushed between the lift and other objects. Compliance is easy when you have the enclosed safety material in your hands.

Scissor lifts are a type of Aerial Lift used to safely move workers vertically. OSHA regulates scissor lifts under the “Scaffolding Standard”. Hazards include falling from lifts, tipping over, and being crushed between the lift and other objects. Compliance is easy when you have the enclosed safety material in your hands. -

A major cause of fire, explosions, and burn injuries. Other hazards include toxic fumes, gases, radiant energy and electrical. Hexavalent Chromium, Cr(VI), is known to cause cancer. It targets the respiratory system, kidneys, liver, skin and eyes. Check out all the available resources to help the Safety Director better understand the hazards and regulatory requirements.

A major cause of fire, explosions, and burn injuries. Other hazards include toxic fumes, gases, radiant energy and electrical. Hexavalent Chromium, Cr(VI), is known to cause cancer. It targets the respiratory system, kidneys, liver, skin and eyes. Check out all the available resources to help the Safety Director better understand the hazards and regulatory requirements. -

The purpose of a Hazard Communication Program is to protect people from injuries and illnesses associated with using hazardous chemicals in the workplace. People have the right-to-know and understand the hazards and identities of the chemicals they are exposed to at work. Key requirements are: Written Plan, Chemical Inventory, Safety Data Sheets, Proper Labeling and Employee Training.

The purpose of a Hazard Communication Program is to protect people from injuries and illnesses associated with using hazardous chemicals in the workplace. People have the right-to-know and understand the hazards and identities of the chemicals they are exposed to at work. Key requirements are: Written Plan, Chemical Inventory, Safety Data Sheets, Proper Labeling and Employee Training.